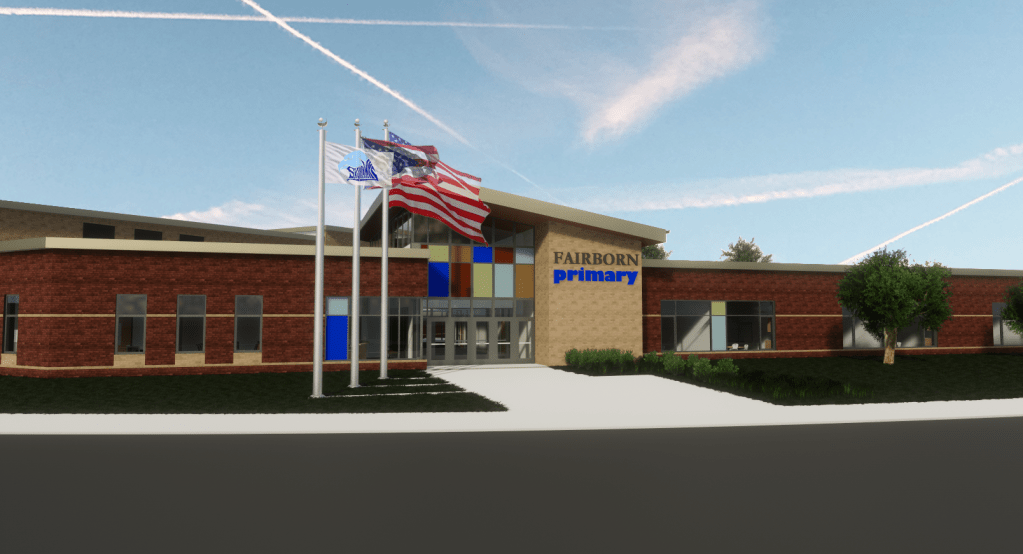

Ohio leads the entire planet in green K-12 schools projects and has for many years. This leadership stems from Ohio Facilities Construction Commission policy of mandating LEED Silver on projects co-funded by the agency. This policy was adopted in 2007 and has since achieved 353 (as of May 2020) LEED certified schools and counting, touching nearly every area of Ohio. In 2016, OFCC leaders foresaw a potentially rocky transition from LEED for Schools v2009 to v4 (and now v4.1). Specifically, this is due to the added emphasis in v4 on site attributes most commonly associated with urban settings (more on this topic to come in future posts). The vast majority of Ohio facilities are built in rural school districts with no hope for access to transit, development density, or diverse uses. In anticipation of these challenges, OFCC pre-registered dozens of future projects in LEED v2009. As a result, Ohio in particular still has a multitude of active legacy LEED projects in an era where v4 & v4.1 are the norm almost everywhere else and has been for some time. Most of these legacy v2009 projects have already completed construction or will by the end of 2021. The project in this example, Fairborn PK-2, is wrapping up construction in early summer 2020.

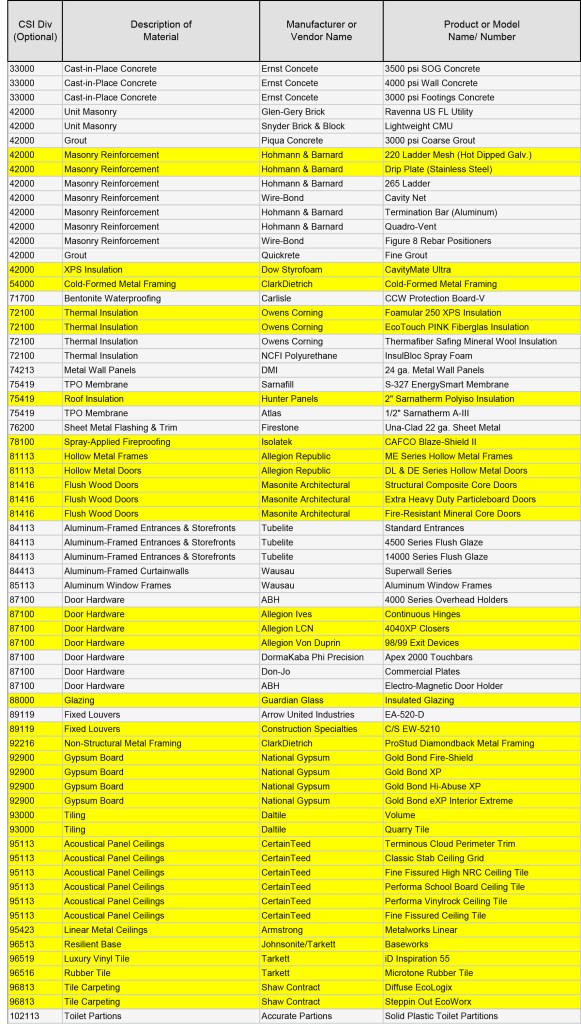

The project in this example, Fairborn PK-2, is wrapping up construction in early summer 2020. EA Energy Solutions has been proud to support Monarch Construction on this project, our third with them. A fun bonus for me is that this project was designed by SHP, my old firm. As you can see by the renderings above, they did a great job! I think it’s important to note that the team did not begin the project with the intent to incorporate any v4 credits. In fact, as LEED v2009 schools go, everything about documenting this project’s construction credits was pretty routine. I spent most of 2019 deep into v4 materials research, so whenever I was reviewing submittals for Fairborn, I took comfort knowing I would be hunting down minimal emissions testing paperwork. I also could not help but notice how many of the products showing up in Fairborn submittals were the same ones I had been collecting EPD’s, HPD’s, Declare Labels, etc. all year long. Once I finished populating the v2009 Excel calculator, I was easily able to scan down the list of products and call out “That door hardware has an HPD,” “That ceiling tile has an EPD,” etc. I quickly was able to count what appeared to be 40+ products that would contribute to either the EPD credit, Materials Ingredients, or both. My first reaction: “We’re going to be just fine on OFCC v4 projects earning BPDO.” This was quickly followed by my second reaction: “Why shouldn’t Fairborn get credit for this?”

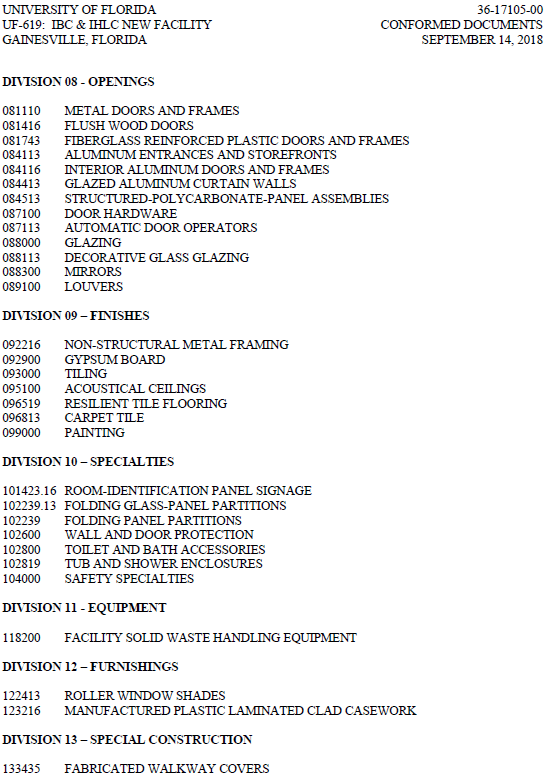

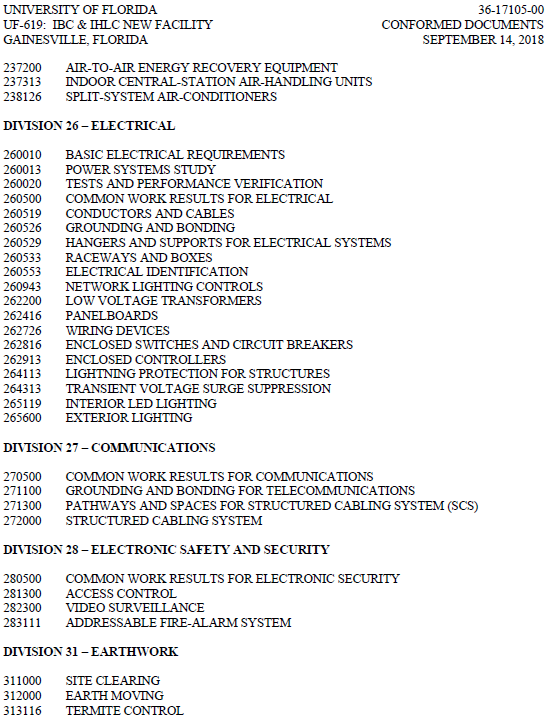

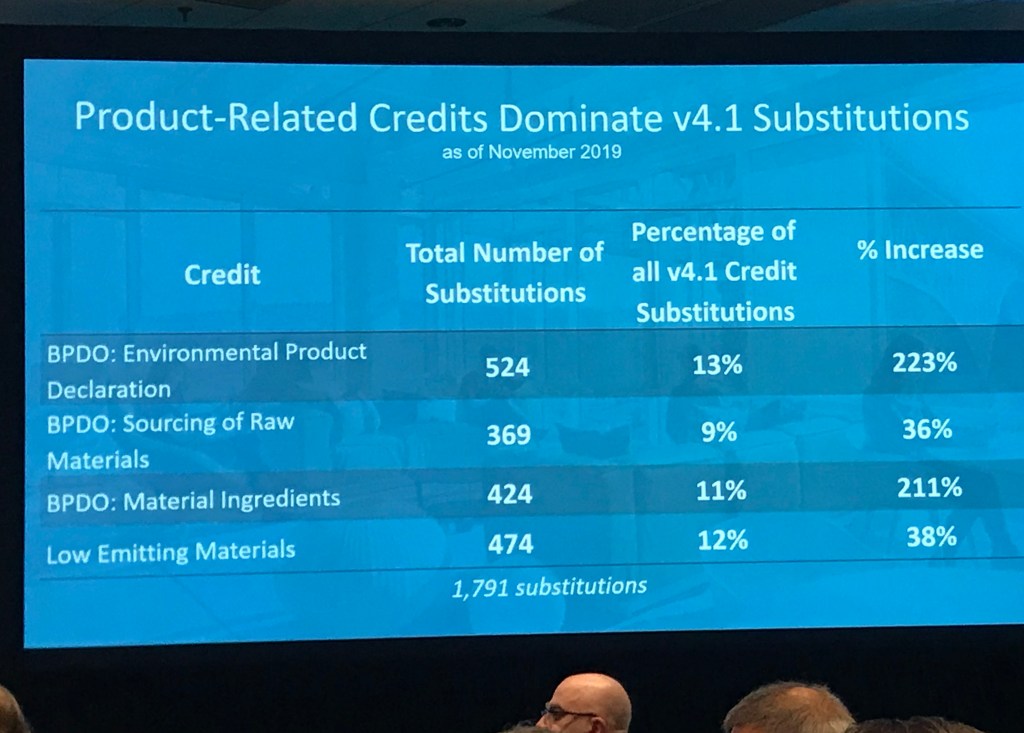

LEED has always allowed project teams to substitute more stringent credit requirements from more newer versions of the rating system. But for our team, there wasn’t any upside to upgrading from v2009 Recycled Content, Regional Materials, etc. We were poised to score really well on the existing credits, and the net amount of LEED points available would not increase. All that would accomplish is to subject the team to more stringent requirements for the same amount of points. But why should we have to substitute? When v4 was released, the previous Materials & Resources credits underwent a substantial overhaul, perhaps one of the most dramatic across the entire rating system. Most of the old credits were reconstituted into Sourcing of Raw Materials, and the EPD and Materials Ingredients credits were newly introduced. Our logic was simple: “If a v2009 project were able to achieve a base v4 point whose concepts were not part of v2009, shouldn’t that count as an Innovation in Design point?”

I was thrilled with the potential of this theory. If accepted, this would be a huge coup for my v2009 projects. If the theory panned out, this would be every bit as reliable as buying Green Power points, the kind of move that can achieve the crucial extra point or two that makes the difference between LEED Silver or LEED Gold. The next step in the experiment was to test this theory with USGBC/GBCI to find out if the logic would hold up under scrutiny. To accomplish this, I enlisted the help of Todd Hager, LEED Project Manager with OFCC. OFCC has strong ties to the Center for Green Schools, and I suspected that our proposed strategy would find favor with them. The hunch was correct, and technical team at USGBC provided us with the following guidance to formalize the use of v4.1 BPDO on v2009 projects:

“THE OTHER OPTION IS TO TRY OUT THE V4.1 REQUIREMENTS AND SUBMIT AS A NEW INNOVATION CREDIT. OUR STAFF WOULD ACTUALLY PREFER THIS OPTION BECAUSE WE ARE TRYING TO GET AS MUCH FEEDBACK AS POSSIBLE ABOUT HOW THESE NEWLY-WRITTEN V4.1 MATERIALS CREDITS ARE WORKING FOR USERS OF LEED.

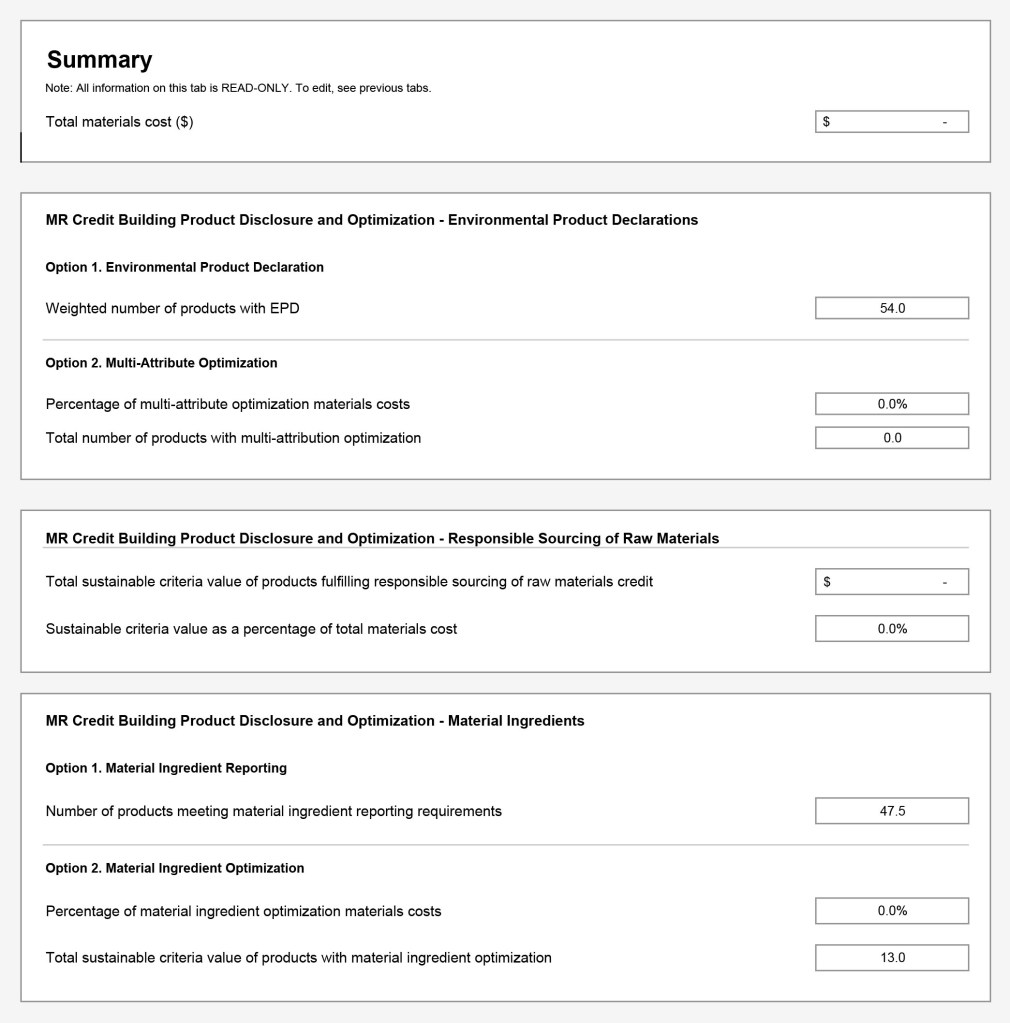

This was exactly the answer I was hoping for! I promptly began the work of inputting materials into v4.1 BPDO calculator. I’m a major proponent of stockpiling LEED documents with the goal of creating an organized library. Due to the volume of LEED submittals I review, I was able to amass a substantial library in a year’s time. The aim of creating this library is to have the ability to efficiently find and pull a given product’s BPDO & Low-Emitting materials documents once that product has been identified via submittal review. In this case, because I had already identified all the products for the original v2009 credits, all I had to do now scroll through the library and pluck the docs I needed. Before l had finished my morning coffee, we were able to round up enough to earn exemplary performance in both EPD Option 1 and Materials Ingredients Option 1. As a kicker, we even had enough products with Cradle2Cradle certificates, etc. to qualify for Materials Ingredients Option 2! The below screenshot from the v4.1 BPDO calculator outlines our results:

Based on these early successful outcomes, I immediately moved to begin adopting this approach on all of my v2009 projects, including the OFCC co-funded Thomas Ewing and General Sherman Junior High Schools in Lancaster, Greenon PK-12, Waynesville Elementary School. In the case of the Ohio Stadium Upgrades, there’s a high probability these points actually will make the difference between LEED Gold and LEED Silver. A slew of these projects will go through the Construction Preliminary Review by GBCI in the near future, so watch for additional posts with a significant sample size of results!