I was fortunate to be able to attend Greenbuild 2019 in Atlanta, Georgia last week. I went down with a mission, and as a result, I laser focused nearly all of my education sessions on one of three topics: Whole Building Life Cycle Assessments & Software, Embodied Carbon, & diving even deeper into advanced LEED Materials credits (New v4.1 BPDO Option 2’s for example). While there, I was involved in a lot of discussion regarding v4 & v4.1 BPDO and Low-Emitting Materials with green building professionals from around the country. When I shared a positive experience with Exemplary Performance I had with Materials Ingredients on a recent project, there were many more surprised faces then I would have expected. The process I used to do this was very straightforward and easily replicated. To that end, I wanted to share it here so that other projects are able to duplicate this result and dispel any notions that BPDO -Materials Ingredients Option 1 is anything but readily achievable across almost or all LEED projects. Exemplary Performance may be even easier then thought as well.

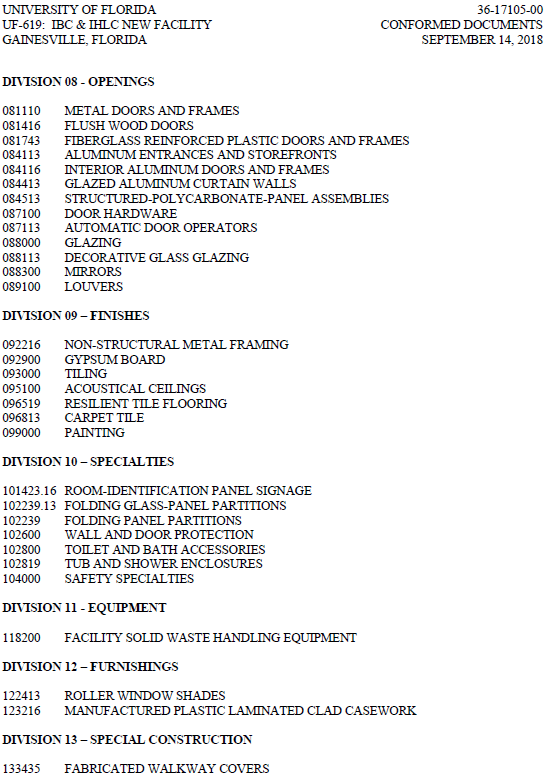

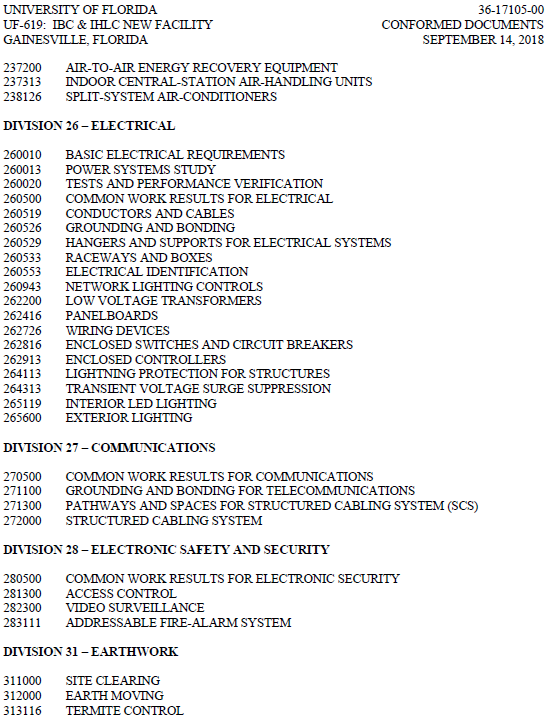

Before I jump into the process, I want to provide some background information on these particular projects and ecoPreserve’s role in them. These points are significant because I think they underscore why these results can be replicated by other project teams. The projects are the Institute for Black Culture and Institute for Hispanic-Latino Cultures at the University of Florida. These facilities, 2019 ULI North Florida Awards Finalists, were designed by DLR Group and built by Foresight Construction Group, respectively. Collectively, they’re approximately 13,000 total sf, and while they’re exceptional buildings built for an exceptional purpose, they are built with conventional construction materials commonly found in most commercial construction projects (see below). ecoPreserve joined Foresight’s team towards the end of construction and our role was simply to assemble the LEED documentation from construction submittals. All of the credit for material selection and procurement that made this exemplary performance even possible goes to DLR Group and Foresight.

Our process to achieve this credit began pretty simply: An exhaustive review of all of Foresight’s submittals to determine what materials were procured within each specification section. This process was aided considerably by Foresight’s adoption of the Procore project management software. The ecoPreserve team, comprised of Jessica Wright, Oscar Vargas, and myself divided up the spec book and began compiling a list of all the materials and manufacturers. It’s important to note here that if you dive into submittals with the expectation that you’ll come up with 20 or 40 HPD’s with no additional research, you’re in for a disappointment. The primary objective of the initial submittal review is to determine what the subcontractors bought. If you can figure out what exact make and model of the materials that were bought first and foremost, you can Google your way to the rest. This whole process is also easier if you name, organize, and stockpile this information while you collect it, so you can reuse on the next project. After a few projects, you can collect a pretty robust library of many of the “usual suspects” materials seen over and over again. You also learn of many materials categories that are an abundance of HPD’s and other equivalent documentation. The overwhelming majority of contributing products will be found within Division 09 submittals. In our example, Finishes represented 21 of the products where we discovered Materials Ingredients documentation, so 100% of what we needed to earn our first Option 1 point. However, if you were to focus solely on Finishes, I can tell you with absolute certainty that MI opportunities are being left on the table. For example, as noted here by GreenBadger, Door Hardware can often account for a significant percentage of the 20 product or 40 product target thresholds. In our particular example, door hardware accounted for 4 of our Materials Ingredients products (and 6 EPD’s as well). Our full list of contributing products (and their divisions) are listed below:

| Spec Section | Manufacturer | Product | Document Type |

| 054000 | ClarkDietrich | Cold-Formed Metal Framing | HPD |

| 071700 | Cetco | Voltex Bentonite Geotextile | HPD |

| 071700 | Cetco | Aquadrain 15X | HPD |

| 071700 | Cetco | Bentoseal | HPD |

| 072100 | Johns Manville | Formadehyde Free Fiberglass Insulation | HPD |

| 074646 | DuPont | Styrofoam Ultra SL XPS Insultation | Maunfacturer Inventory |

| 081110 | Ceco/Assa Abloy | Series SU Hollow Metal Frames | HPD* |

| 081110 | Ceco/Assa Abloy | Regent Hollow Metal Doors | HPD |

| 087100 | McKinney/Assa Abloy | Standard Door Hinge | HPD |

| 087100 | Rockwood/Assa Abloy | K1050 Kickplate | HPD |

| 092216 | ClarkDietrich | ProStud Non-Structural Metal Framing | HPD |

| 092900 | National Gypsum | Gold Bond Fire Shield Shaftliner Gypsum Board | HPD |

| 092900 | National Gypsum | Gold Bond Fire Shield Gypsum Board | HPD |

| 092900 | National Gypsum | PermaBase Gypsum Board | HPD |

| 092900 | National Gypsum | Gold Bond eXP Tile Backer Gypsum Board | HPD |

| 092900 | National Gypsum | ProForm XP Lite Joint Compound | HPD |

| 093000 | Daltile | Annapolis Sail Tile | HPD |

| 093000 | Daltile | Jewel Tide Tile | HPD |

| 093000 | Dailtile | Rittenhouse Arctic White Tile | HPD |

| 093000 | MAPEI | Ultraflex LFT Mortar | Manufacturer Inventory* |

| 093000 | MAPEI | Aquadefense Crack Isolation Membrane | Manufacturer Inventory* |

| 093000 | MAPEI | Kerapoxy Epoxy Grout | Manufacturer Inventory* |

| 093000 | MAPEI | ECO 575 Adhesive | Manufacturer Inventory* |

| 096813 | Interface | Summerhouse Shade Carpet Tile | HPD |

| 096813 | Interface | Interface French Seams Carpet Tile | HPD |

| 096813 | Mohawk Group | Step in Style II Carpet Tile | Declare |

| 099000 | Sherwin Williams | ProMar 200 Interior Latex Flat | UL Product Lens* |

| 099000 | Sherwin Williams | ProMar 200 Interior Latex Semi-Gloss | UL Product Lens* |

| 099000 | Sherwin Williams | PrepRite Latex Block Filler | UL Product Lens* |

| 099000 | Sherwin Williams | Loxon Masonry Primer/Surfacer | UL Product Lens* |

| 099000 | Sherwin Williams | Pro Industrial DTM Primer/Finish | UL Product Lens* |

| 123216 | Formica | Compact Laminate | HPD |

| 123216 | Formica | High Pressure Laminate | HPD |

| 142400 | ThyssenKrupp | Create a Cab Elevator Cab | Cradle2Cradle* |

| 142400 | ThyssenKrupp | Elevators Doors & Entrances | Cradle2Cradle* |

| 220700 | Knauf | Earthwool 1000 Pipe Insulation | Declare |

| 230713 | Knauf | Atmosphere Duct Wrap | HPD |

| 230716 | Knauf | Duct Insulation Board | Declare |

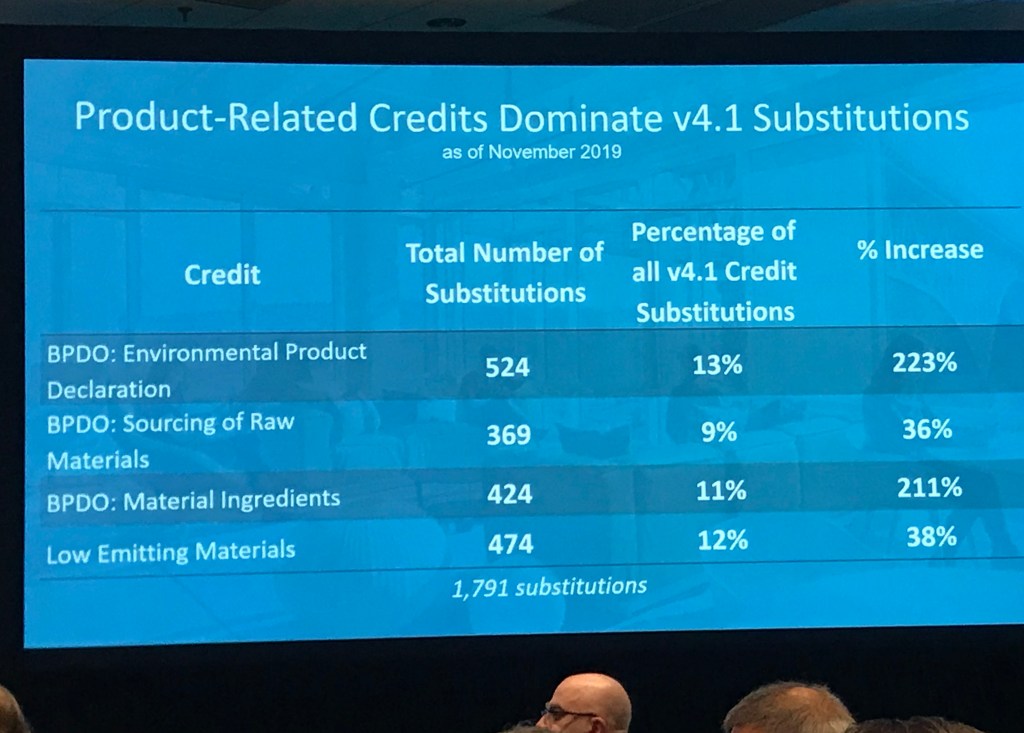

If you’re playing along at home, you have likely noticed two things: Some of the documents we’ve gathered have asterisks (*) next to them, and there are only 38 products listed here, as opposed to the 40 products needed to earn the Exemplary Performance point. This is the point where our plot twist is introduced: We’re upgrading to LEED v4.1! While version v4.1 is in beta, project teams have the ability to selectively substitute v4.1 credit requirements in where it is advantageous to their project. For some credits, including BPDO, I highly recommend making this switch, and in a minute, you’ll see why. At the same Greenbuild session I attended, USGBC provided some data on which credits they have seen projects upgrading most often:

As you can see above, this credit represents 11% of all LEED v4.1 substitutions made to date, now let’s see how it impacts our project. One of the big changes to the credit requirements, as outlined here by LEEDuser.com, “Any compliant reports above with third-party verification that includes the verification of content inventory are worth 1.5 products for credit achievement calculations.” Remember all of our document types in the above table with the asterisks? Those 12 documents are now all worth 1.5 each instead of 1. Our 38 (38 x 1) has now become 44 (38 – 12 = 26. (26 x 1) + (12 x 1.5) or 26 + 18 = 44). These 12 documents, UL Product Lens, Cradle2Cradle, a 3rd Party Verified HPD, etc. have put us over the top, and we’ve exceeded the threshold of 40 products across 5 manufacturers to achieve Exemplary Performance!

To summarize, the main theme here is to emphasize that these points are readily achievable. We didn’t have an elaborate process to maximize the number of products that complied during procurement, we didn’t reinvent the wheel to exceed 40 products. It wasn’t rocket science or a magic trick either. The real trick to getting these points for the owner, the facilities, and our other project teams members really came down to just a simple exercise of exhaustive due diligence!